Living nowhere...Building on the lessons of affordable housing

Barely a year after it ended, Germany had built 350,000 new homes out of the ashes and devastation of the Second World War, and in 1951 a young (ish) Harold Macmillan promised that, if elected, the Conservatives would build 300,000 houses a year in the UK: and the Conservatives were duly elected, predictably falling short of their target but still building no less than 200,000 new homes before the year was out. Falling short maybe, but dwarfing the paltry 6,287 affordable homes built in the UK last year, and especially so when you take into account that over the same period 23,740 affordable homes were either sold or demolished in Britain.

Just stop and think about that a moment…

In war-ravaged Germany builders achieved 48 completions an hour, while in war-winning but hardly less ravaged Britain, and despite rationing restrictions and the worst winter for years (not to mention broken election promises), contractors were still managing to build 548 new, affordable homes every day. But today, the United Kingdom, the fifth-biggest economy in the world, is struggling to build 12 new affordable homes a month. And in the United States the position is even worse: Reagan and Clinton era policies mean Public Housing is created only when it is needed to replace existing stock, which more or less means nothing is built at all. So at the moment, nobody in the United States working 40 hours a week and earning minimum wage can afford to move into a standard two-bedroom apartment. They’re literally living nowhere…

So what went wrong?

Well, as so often history offers a clue. Back in 1950’s Britain Laing had invented a new way of building houses called Easiform: pouring concrete into prefabricated frames on-site and pebble dashing the unit later, enabling them to build 1000 new houses a month in Plymouth alone (despite the severe winter conditions). George Wimpey had devised a popular “no-fines” construction method, setting coarse concrete into house-shaped moulds and establishing a precedent for what is still the most ubiquitous building format in the United Kingdom. But with the subsequent decline in funding for public housing programmes from the 1970s onwards, this thirst for innovation seems to have declined too, markedly reducing delivery rates.

And of course, perhaps inevitably, COVID has a part to play in all this as well: according to a recent OECD study (“Tackling the Coronavirus: Housing Policy and Public Sector Strategy”), the pandemic has markedly destabilised real estate sectors across the globe and affordable housing in particular. Based on a newly created analogue of the Purchasing Manager’s Index (or PMI), a key indicator of consumer confidence levels, the Report found a slump in confidence directly attributable to lockdown measures and went on to forecast a severe time lag before construction levels get back to anything close to pre-pandemic levels. And despite the fact most Governments across the Planet have since introduced policies to protect vulnerable housing groups, including suspension of eviction procedures and a moratorium on rent and mortgage payments, none of these policies will help get more homes built: in fact, they may disincentivise developers from building affordable housing. In the current climate, instead of creating new homes for those in need, contractors may (and probably will) prefer to build yet another glass tower block where Russian oligarchs can snap up by apartments by the dozen and leave them unoccupied until markets rise again.

That’s why the OECD recommends an expansion of capital spending on affordable housing, improving near term affordability and long term supply as well as accelerating the spread of new and improved building technologies such as modular construction: technologies that are capable of speeding up delivery rates when they’re most needed, better aligned to environmental transition and sustainability objectives: in short, technologies that are the direct descendants of Laing’s Easiform moulds back in the 1950s.

Well, after all, the technological change worked then…why not now.

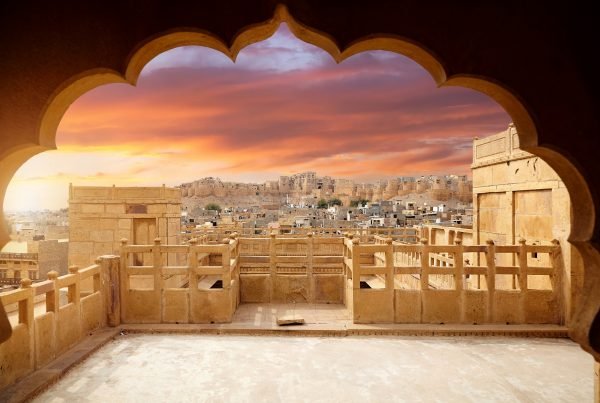

Modulex Construction is the World’s largest and India’s first Steel Modular Building Company. It was established by Red Ribbon to harness the full potential of these fast-evolving technologies and deliver at a pace to meet the evolving needs of the community.

Executive Overview

Sadly, we’re facing acute and unprecedented shortages of affordable housing stock across the globe, and it’s proving to be a real shock to existing supply chains. Like many of us, I just don’t believe conventional construction technologies are capable of rising to the challenge this requires: with the pace, volume and quality it demands.

That’s why I’m confident Modular Construction is so important for all our futures: delivering at pace, working off a low-cost platform and incorporating levels of quality assurance that conventional technologies simply can’t match.

Leave a Reply